Nailing in geotechnical engineering refers to the use of structural nails, typically made of steel, to reinforce soil or rock. Nailing is often used in excavation support systems, slope stabilization, and foundation construction.

In excavation support systems, nails are used to provide additional support for the excavation walls to prevent soil or rock collapse. They are typically installed at an angle and are anchored into the ground using grout or cement.

In slope stabilization, nails are used to reinforce unstable slopes and prevent landslides. This is done by drilling holes into the slope and inserting the nails, which are then grouted in place. The nails provide additional support to the soil or rock, increasing its strength and stability.

Excavation stabilization using soil nail walls and anchoring system-Farmaniyeh project

In foundation construction, nails can be used to provide additional support to the foundation. This is especially important in areas with weak or unstable soil, where the foundation may be susceptible to settling or shifting over time. Nails can be installed around the perimeter of the foundation to reinforce the soil and provide additional support.

The process of installing

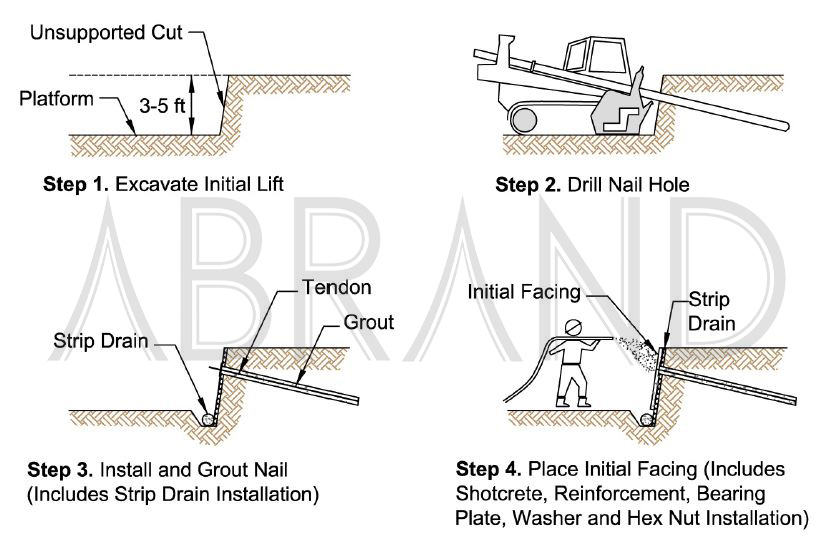

The typical sequence of construction of a soil nail wall is described below and shown schematically

the soil nail installation process involves six steps. The first step is excavation, which involves digging a hole that is typically 3 to 5 feet deep and wide enough to accommodate the soil nail installation equipment. The excavation face must be able to remain unsupported until the nails and initial facing are installed, which usually takes one to two days. The type of soil being excavated may limit the depth of the excavation.

The second step is drilling the nail holes, which is done using specialized equipment from the excavated platform. The drill holes are typically left unsupported.

The third step involves installing the nails and grouting them in place. Strip drains are also installed on the excavation face between adjacent nails.

The steps of soil nail wall installation

The fourth step is constructing the initial shotcrete facing, which involves applying a lightly reinforced 4-inch thick shotcrete layer to the unsupported cut. The shotcrete is cured for at least 72 hours before proceeding with subsequent excavation lifts.

The fifth step involves repeating steps one through four for the remaining excavation lifts, including unrolling the strip drain and overlapping the WWM panel above.

The sixth and final step is constructing the final facing, which may consist of CIP reinforced concrete, reinforced shotcrete, or prefabricated panels. Drainage systems are installed to discharge any water that may collect in the continuous strip drain.

Advantages and limitations of soil nail walls

The use of nailing systems in geotechnical engineering offers several advantages, including:

Increased stability: Nailing systems can increase the stability of soil or rock by reinforcing it and improving its resistance to external forces.

Flexibility: Nailing systems are flexible and adaptable to different soil and rock conditions. They can be installed at different angles and depths, making them suitable for a variety of geotechnical applications.

Cost-effective: Nailing systems are often less expensive than other stabilization methods, such as reinforced concrete walls or soil nails, making them a cost-effective solution for many projects.

Minimal disruption: The installation of nailing systems is typically less disruptive than other stabilization methods, as it requires smaller equipment and can be completed more quickly.

Environmental benefits: Nailing systems can be designed to minimize the disturbance to the surrounding environment, making them a more environmentally friendly option than other stabilization methods.

Versatility: Nailing systems can be used in a variety of geotechnical applications, including slope stabilization, excavation support, and foundation construction, making them a versatile solution for many projects.

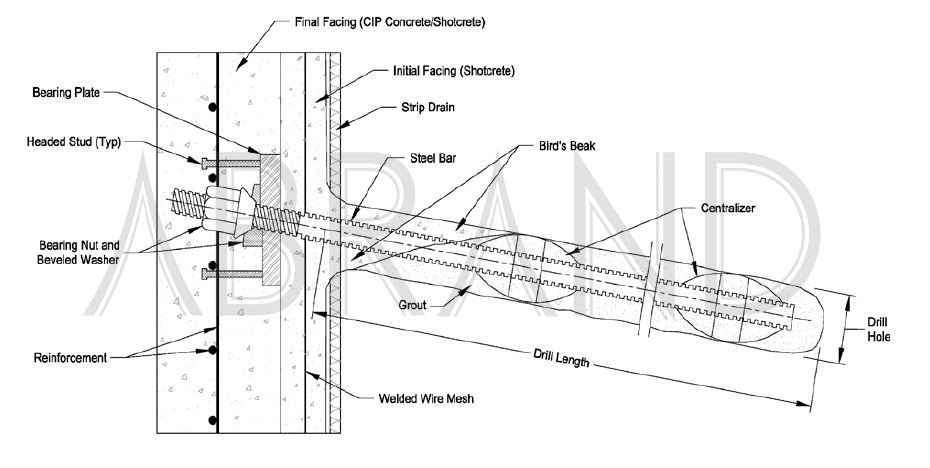

Components of a nail

Main limitations

In construction projects where stringent wall movement criteria are in place, it may be necessary to take additional measures to limit deflections, which would increase the cost of the project.

If the movement criteria are extremely strict, soil nails may not be a feasible solution.

The presence of utilities behind the wall can limit the location, inclination, and length of soil nails, particularly in the upper rows.

Soil nail walls are also not suitable for sites where large amounts of groundwater seep into the excavation, as the walls require maintaining a temporary unsupported excavation face during construction.

Permanent soil nail walls require permanent underground easements, and soil nail tendons may interfere with certain types of communication lines, such as optic fiber, that run immediately adjacent to the wall.

English

English