In geotechnical engineering, anchoring refers to a technique used to stabilize structures or slopes in soil or rock by transferring the loads to a deeper and more stable layer. Anchors are typically made of high-strength steel tendons or rods that are grouted into a borehole that has been drilled into the ground. The anchoring system may take the form of a tieback, which is used to resist lateral forces on retaining walls or excavation support systems, or a ground anchor, which is used to resist uplift forces on foundations or other structures.

Anchoring is commonly used in geotechnical engineering for a variety of applications, such as stabilizing slopes, retaining walls, bridge abutments, towers, and other structures. The design of the anchoring system typically involves a detailed analysis of the soil or rock conditions, the loads to be resisted, and the characteristics of the anchor and grout materials. The performance of the anchoring system is also monitored over time to ensure its continued effectiveness.

Stabilization of deep excavation employing nails, anchors and soldier beams-Farmaniyeh project

The process of installing anchors

Anchoring is an important technique in geotechnical engineering because it allows structures to be built in areas where the loads on the structure are too great for the soil or rock to support on its own. By transferring the loads to a deeper and more stable layer, the anchoring system can provide additional stability and prevent the structure from settling, sliding, or collapsing.

Read more: Deep soil mixing method

The design of an anchoring system involves several factors, including the soil or rock conditions, the loads to be resisted, the type of anchor to be used, and the characteristics of the grout material. The design must also take into account the potential for corrosion of the anchor material, which can weaken the anchoring system over time.

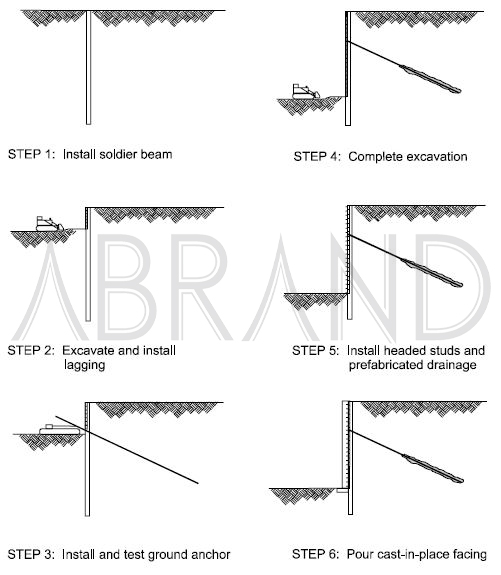

The steps of installing anchors in excavation projects

The implementation of the anchoring method consists of several steps which are described as below:

- The first step is placing the soldier beams in the planned location at the boundary of the excavation site, next to the neighbor’s field.

- The next step includes excavation to desired level which is, usually, 2 to 3 meters, and then meshing and spraying shotcrete on the face of the excavation.

- Next, a borehole is drilled into the soil using specialized equipment. The diameter and depth of the borehole depend on the anchor size and length.

- Then the anchor is inserted into the borehole and secured in place using grout. The grout is typically a cement-based mixture that is injected into the borehole under pressure, filling any voids and creating a bond between the anchor and the surrounding soil or rock.

- After the anchor is installed, a hydraulic jack or other device is used to apply a pre-determined tension or load to the anchor. The tension is typically applied in stages to allow for adjustments and to ensure that the anchor is not overloaded.

- Once the pre-tensioning is complete, an anchor head is attached to the anchor. The anchor head is typically a steel plate or other device that is used to connect the anchor to the structure being stabilized.

- After the anchor is installed and pre-tensioned, it may be subject to load testing to verify that it can resist the required loads. Load testing involves applying a known load to the anchor and measuring the resulting movement or deformation.

A stabilized wall by the anchoring system

Once an anchoring system has been installed, it is typically monitored over time to ensure that it continues to provide the necessary stability. Monitoring may involve visual inspections, load testing, and instrumentation to measure the movement and stress in the anchor and the surrounding soil or rock. If any issues are identified, the anchoring system may need to be repaired or replaced to ensure the continued safety and stability of the structure.

Advantages and disadvantages of the anchoring system

The main advantages of anchoring in geotechnical engineering are:

- Increased stability: Anchoring provides additional stability to structures by transferring the loads to a deeper and more stable layer. This allows structures to be built in areas with poor soil or rock conditions, or in areas where the loads on the structure are too great for the soil or rock to support on its own.

- Cost-effective: Anchoring can be a cost-effective solution for stabilizing structures, as it often requires less excavation and material removal than other stabilization techniques. In some cases, anchoring can also be used to retrofit existing structures, which can be a more cost-effective solution than rebuilding the entire structure.

- Versatility: Anchoring can be used for a variety of applications, including stabilizing slopes, retaining walls, bridge abutments, towers, and other structures. Different types of anchors and anchoring systems can be used depending on the specific needs of the project.

- Durability: Anchoring systems are typically designed to be durable and long-lasting, with a design life of several decades or more. This makes them a reliable solution for stabilizing structures over the long-term.

- Reduced environmental impact: Anchoring can be a more environmentally-friendly solution than other stabilization techniques, as it often involves less excavation and material removal, which can reduce the impact on the surrounding environment.

Read more: Nailing method in deep excavations

While anchoring is a widely used technique in geotechnical engineering, there are some disadvantages or limitations to consider:

- Limited effectiveness in certain soil or rock conditions: Anchoring may not be effective in all soil or rock conditions, particularly in highly fractured or weathered rock, or in soils with very low shear strength. In these cases, other stabilization techniques may be more effective.

- Corrosion: If not designed properly, the anchor material can be susceptible to corrosion, which can weaken the anchoring system over time. This can lead to decreased effectiveness and potential safety hazards.

- Installation difficulties: Installation of anchoring systems can be complex and time-consuming, particularly in areas with limited access or difficult terrain. Specialized equipment and expertise may be required to properly install the anchors.

- Maintenance requirements: Anchoring systems require ongoing maintenance to ensure their continued effectiveness over time. This can involve visual inspections, load testing, and instrumentation to measure movement and stress in the anchor and surrounding soil or rock.

- Cost: While anchoring can be a cost-effective solution in many cases, it can also be expensive, particularly for large or complex projects. The cost of materials, labor, and equipment can add up quickly, and anchoring may not always be the most economical solution for every project.

English

English