The deep soil mixing method is a ground improvement technique used in geotechnical engineering to improve the engineering properties of soils. It involves the mechanical mixing of a soil mass with a binding agent, such as cement or lime, to form a soil-cement or soil-lime mixture. The mixture is then compacted in place, either by the use of a drill rig or by a specialized mixing tool that is inserted into the ground.

Deep soil mixing is typically used to improve the strength, stiffness, and permeability of soft, cohesive soils, such as clays and silts. It can also be used to create retaining walls, foundations, and other structural elements in difficult soil conditions. The technique is often employed in construction projects where existing soil conditions are poor and need to be improved to support the proposed structure.

The advantages of deep soil mixing include its ability to be performed in situ, its cost-effectiveness compared to other ground improvement methods, and its ability to be customized to specific soil conditions. However, it is important to note that the success of deep soil mixing depends on site-specific factors, such as soil type, moisture content, and the type and amount of binding agent used.

Deep Soil Mixing Method for ground improvement

Improvement Purposes

The deep mixing method is a ground modification technique that improves the quality of ground by in situ

solidification of soft soil or by in situ fixation of contaminated ground. In a broad perspective, the main objectives of improvement are to increase strength, to control deformation, to reduce the permeability of loose or compressible soils, or clean a contaminated site. Nevertheless, DM technology has been employed for the following specific purposes:

- Increasing bearing capacity

Reduction of settlement

Prevention of sliding failure

Protecting structures surrounding the excavation site

Controlling seepage and as a cut-off barrier

Preventing shear deformation (liquefaction mitigation)

Remediation of contaminated ground

Increasing drivability for tunneling in soft ground

Ground anchorage

Vibration impediment.

Factors affecting strength

There are numerous factors that influence the strength of artificially cemented ground. Some factors contributing to

the results of a laboratory strength test are as follows:

- physio-chemical properties of the soil in terms of grain size, mineralogy, water content, reactivity, organic content, pH and Atterberg limits.

- quality and quantity of the stabilizing agent and other additives

- mixing and curing conditions in terms of water/cement ratio, mixing time and curing period

- sampling and testing method in terms of sample disturbance, type of laboratory test, strain rate, method of strain measurement, etc.

Correspondingly, it is expected that the properties of stabilized soil prepared in the laboratory will be different

from those in the field. In the following sections, different laboratory methods for estimation of the strength of treated soil are presented.

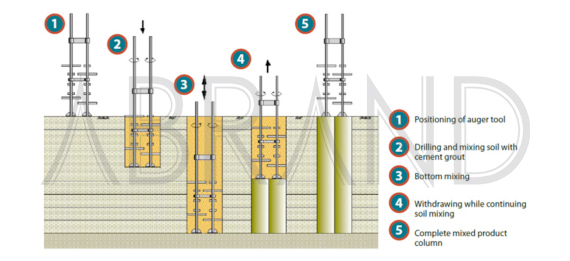

The execution steps of DM columns

The advantages and limitations of DSM method

There are several advantages to using deep soil mixing over other ground improvement methods.

- Deep soil mixing can be performed in situ, meaning that it can be carried out without the need for excavation or removal of soil, which can be time-consuming and expensive. This makes it a faster and more cost-effective option compared to other methods such as soil replacement or soil stabilization using traditional piling techniques.

- Deep soil mixing is a customizable technique. The amount and type of binding agent used can be adjusted to suit specific soil conditions, allowing for greater control over the final properties of the treated soil. This makes it a versatile technique that can be used in a wide range of soil types and conditions.

- It is a relatively low-impact method. It does not require heavy equipment to be transported to and from the site, and the amount of material required is typically smaller compared to other ground improvement methods. This means that it can be a more environmentally friendly option.

- It can create a stronger, more stable foundation for structures. The soil-cement or soil-lime mixture created by deep soil mixing can improve the soil’s load-bearing capacity, stiffness, and shear strength, which can result in a more stable and durable foundation for the structure.

While deep soil mixing has many advantages, there are also some limitations to the technique that should be considered.

One major limitation is that deep soil mixing is not suitable for all soil types. The technique is most effective for soft, cohesive soils such as clays and silts. For other soil types, such as sand or gravel, other ground improvement methods may be more appropriate.

Another limitation is that deep soil mixing requires a certain level of moisture content in the soil to be effective. If the soil is too dry or too wet, the mixing process may not be successful. Additionally, the performance of the treated soil can be affected by the surrounding soil conditions, such as groundwater levels.

The effectiveness of deep soil mixing can also be affected by the quality of the binding agent used. If the binding agent is not mixed thoroughly with the soil or if the quality of the binding agent is poor, the resulting soil-cement or soil-lime mixture may not be effective in improving the soil’s properties.

Lastly, deep soil mixing can be limited by access and space constraints on the construction site. The technique requires specialized equipment, and if the site is difficult to access or has limited space, it may not be possible to carry out the mixing process effectively.

English

English